Color-coded Cleaning System

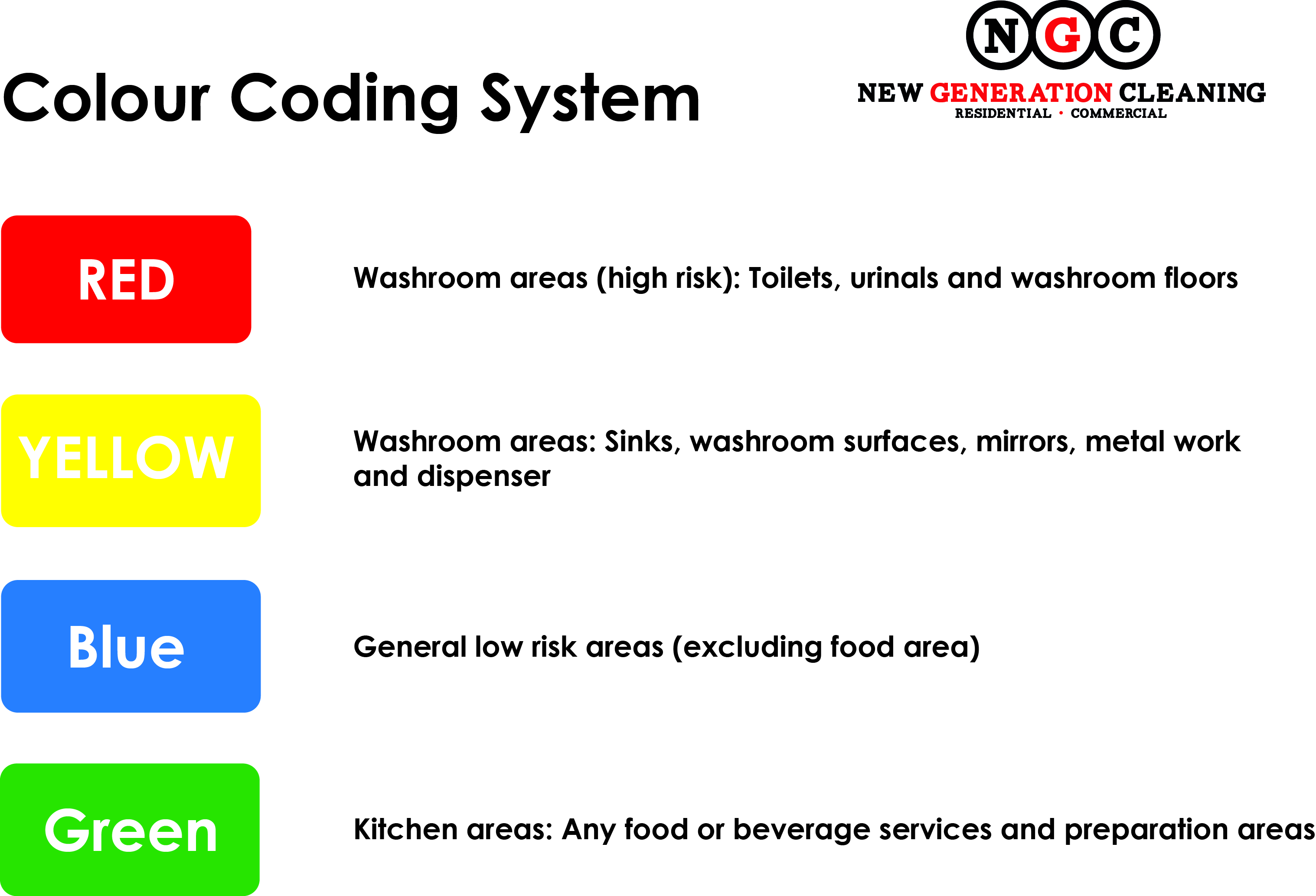

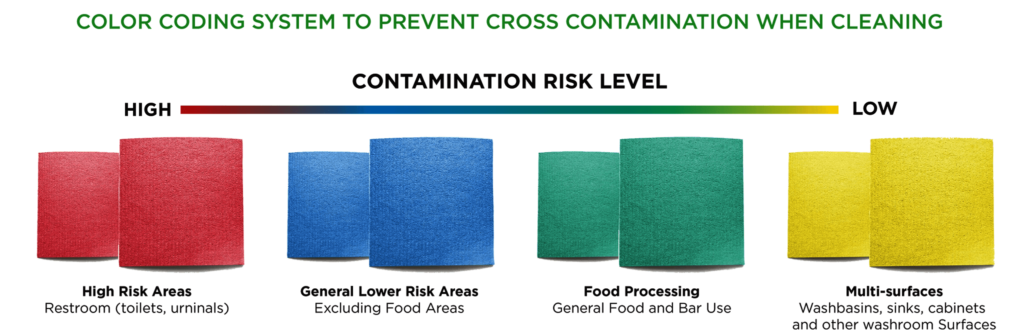

Color-coded cleaning system. Red is a color that is universally associated with risk and hazards. The industry standard color-coding system includes red for high-risk areas such as toilets and urinals. From our exciting color code program comes colorful equipment cleaning brushes.

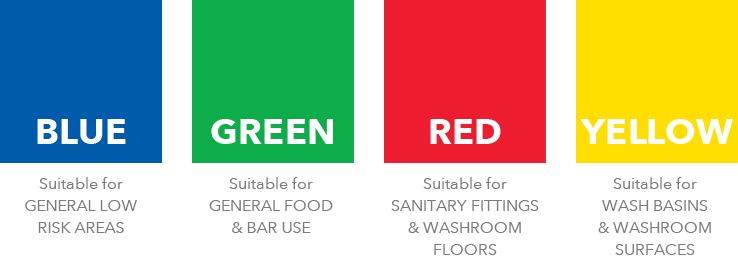

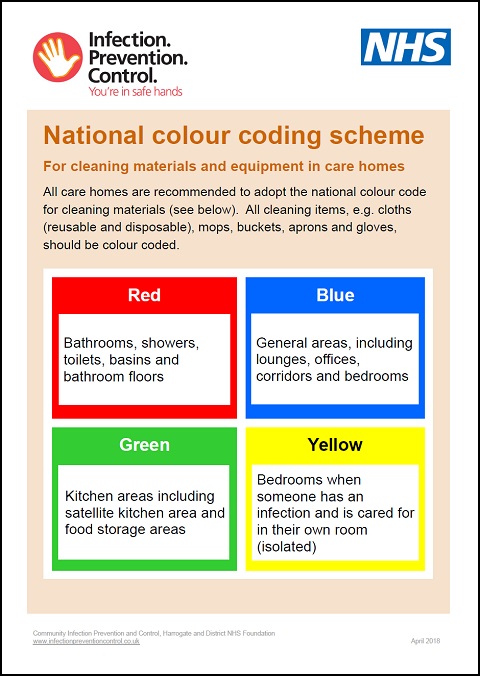

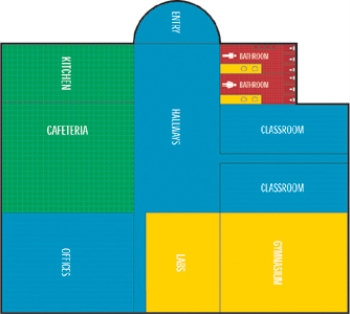

In the BICSc system every major work area has a designated colour code. Color-Coded Microfiber Cleaning Systems Color-Coded Microfiber Mops And Cloths Are Essential For Safe And Efficient Facilities Maintenance The rise of Healthcare Associated Infections HAIs is prolific amongst the elderly sick and young. Blue for all-purpose cleaning dusting window cleaning wiping desks etc in other areas of a facility.

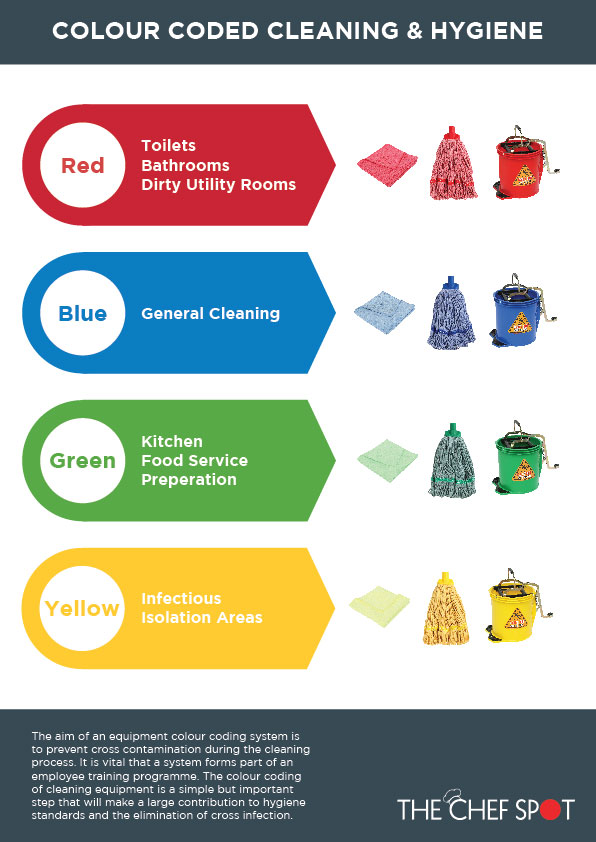

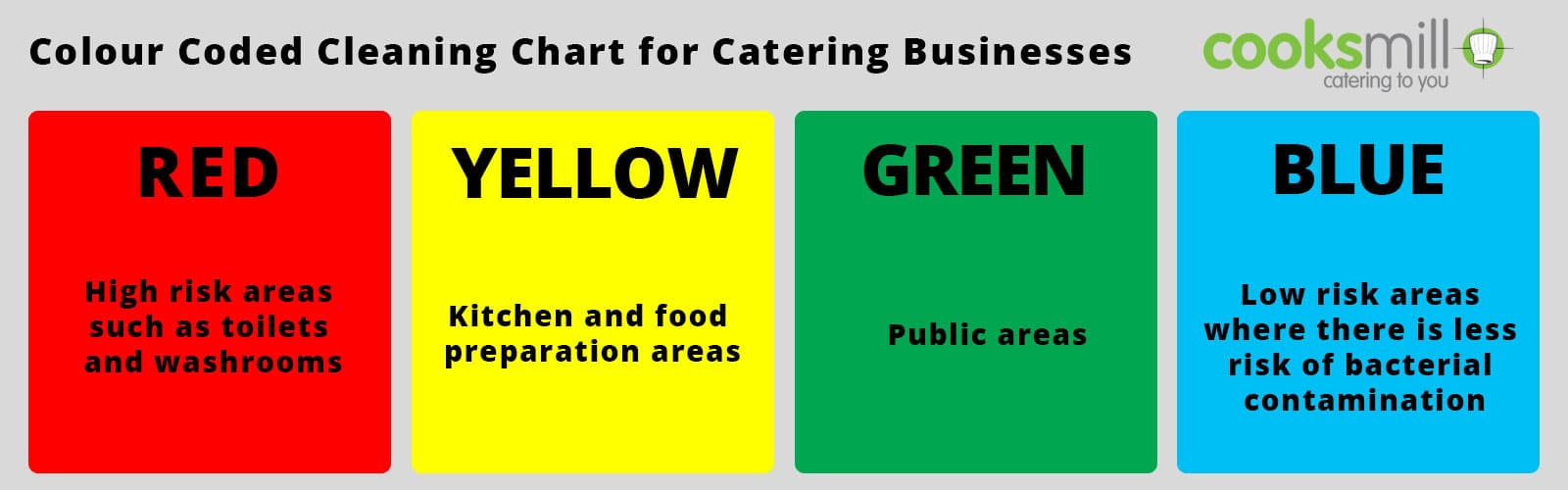

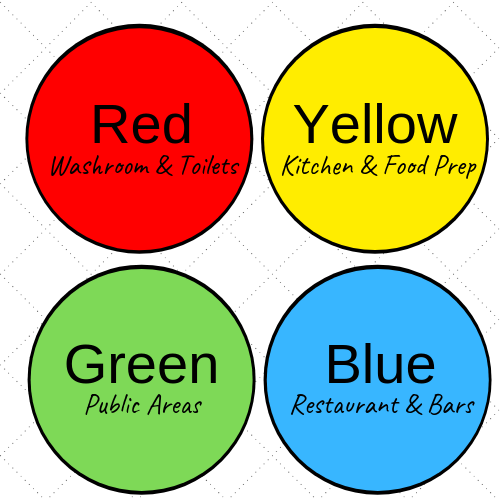

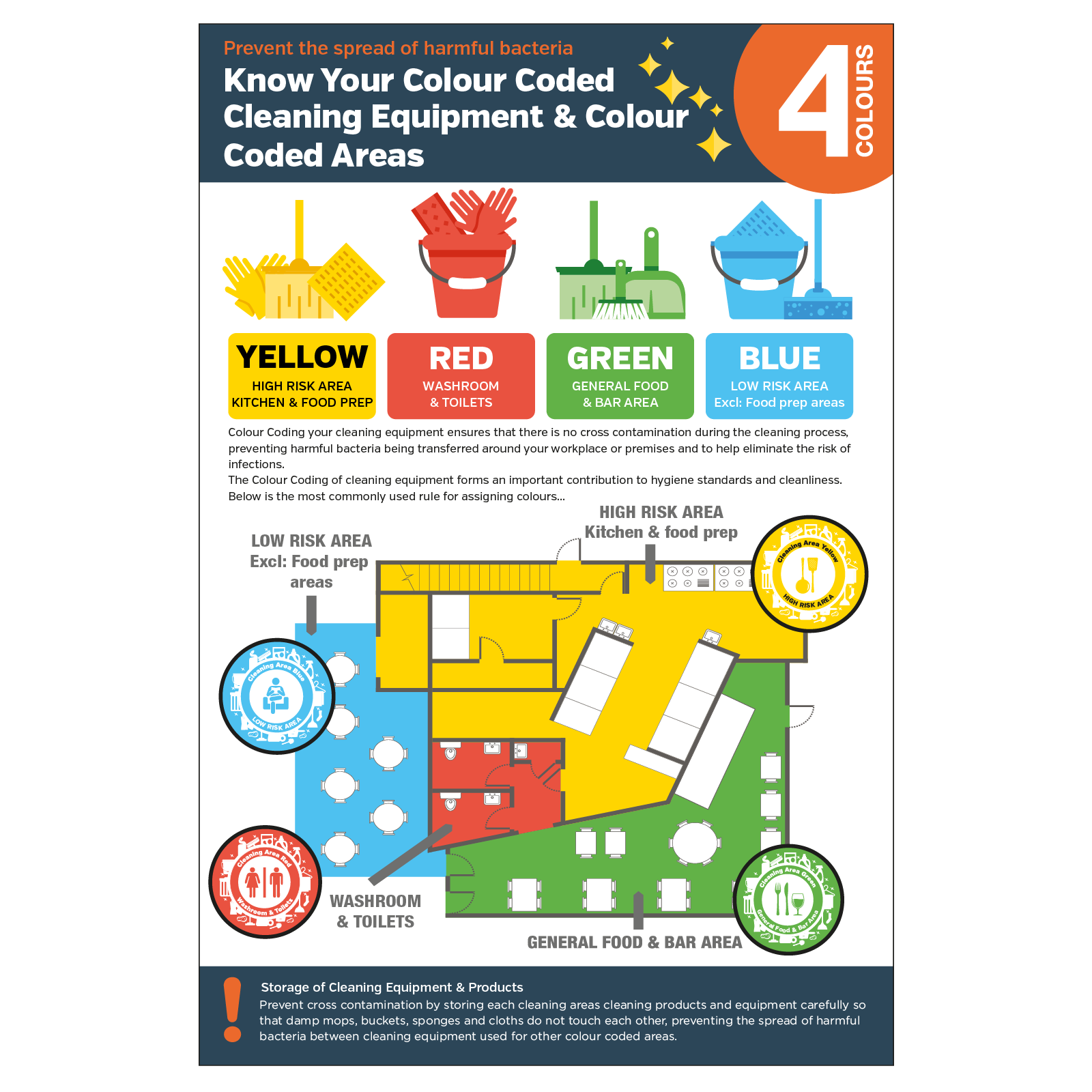

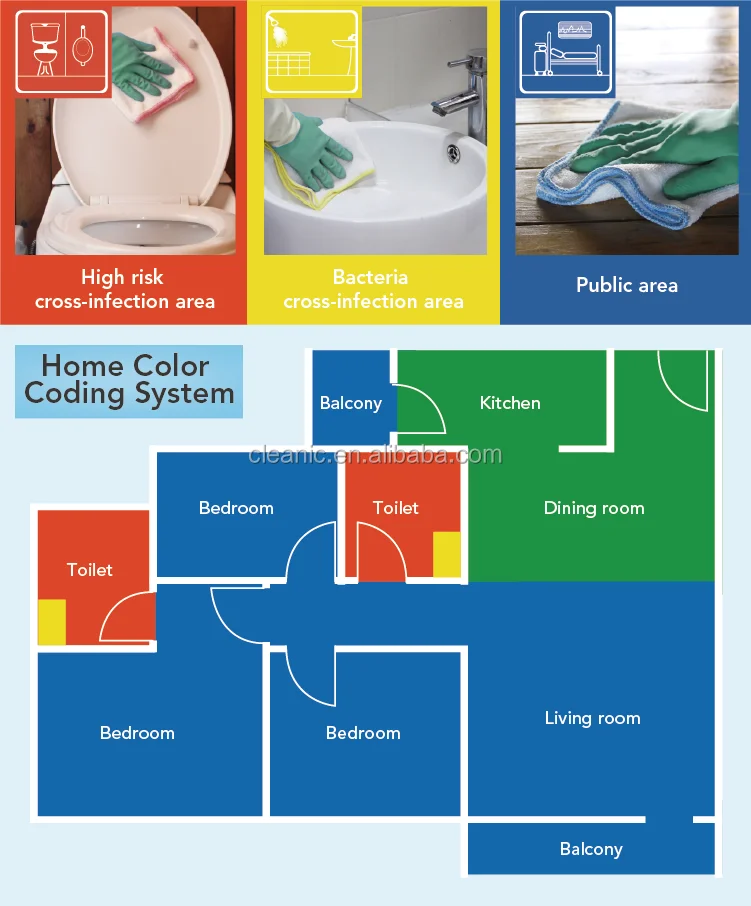

Colour coded cleaning is the process of designating colors to cleaning equipment in certain areas of a premisesproperty reducing the spread of the virus g. Most businesses will benefit from this system by differentiating the color of buckets towels and cloths while reducing confusion and increasing efficiency. Therefore the CCC is an essential staple at any good cleaning company.

Yellow for low-risk restroom areas including sinks and mirrors. Color coded cleaning is the process of using designated colors for different areas when cleaning. The aim of a colour-coding system is to prevent cross-contamination from one cleaning area or surface to another.

Colour coded cleaning is a system adopted by commercial businesses to reduce the risk of cross contamination within their premises. Ad Stone Touch is your complete source for floor care maintenance and restoration. Utilize any of the several available colors to tailor a.

Implementing color-coded cleaning plans in food-safe and hygiene-sensitive environments offers many benefits above all helping to ensure quality and safety in a facility. Getting Front Line Cleaners On Board. It is imperative that staff easily understands.

Blue for all-purpose cleaning dusting window cleaning wiping desks etc in other areas of a facility. A system of colour codes was developed by The British Institute of Cleaning BICSc a leading commercial cleaning body in the 1990s.

The Dutch Maids Color-Coded Cleaning System combines superior microfiber technology designed to dislodge and grab fine particles and oils in the crevices and grain of the surfaces in your home with a color-coding system that eliminates cross-contamination improves performance and leads to a cleaner healthier home.

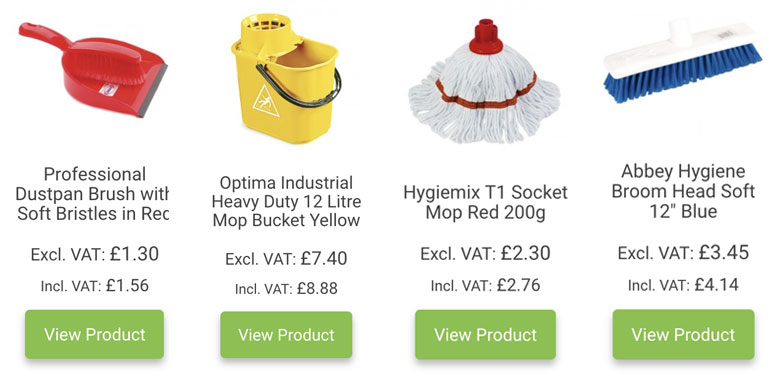

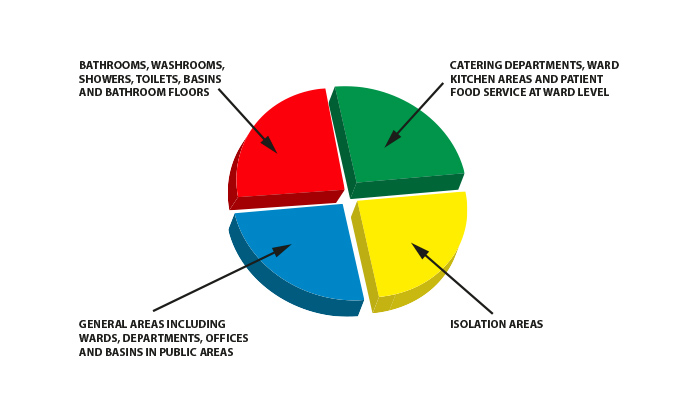

The color-coded program intends to help cleaning companies identify different colored cleaning products cloths mops rags for specific tasks and areas at the facility they maintain. The aim of a colour-coding system is to prevent cross-contamination from one cleaning area or surface to another. The 5 colour codes are red yellow blue green and white. Color coded cleaning is the process of using designated colors for different areas when cleaning. We assign this red color code to areas such as urinals toilets and washroom floors. Colour coded cleaning is a system adopted by commercial businesses to reduce the risk of cross contamination within their premises. And green for food-service areas. Here youll find an overview of the benefits to color-coding an introduction to. A color-coded cleaning program is intended to help you identify different colored cleaning products such as rags towels and cloths and mops for specific tasks.

Getting Front Line Cleaners On Board. These BICSc guidelines are relatively to understand and use yet have still not been adopted by all contract cleaning companies. Therefore the CCC is an essential staple at any good cleaning company. The color-coded handles part of a color-coded cleaning system feature 3 to 7 aluminum telescopic handles. The chart below shows which janitorial areas each of the colors correspond to. And green for food-service areas. A system of colour codes was developed by The British Institute of Cleaning BICSc a leading commercial cleaning body in the 1990s.

Post a Comment for "Color-coded Cleaning System"