Refrigeration Leak Detection System

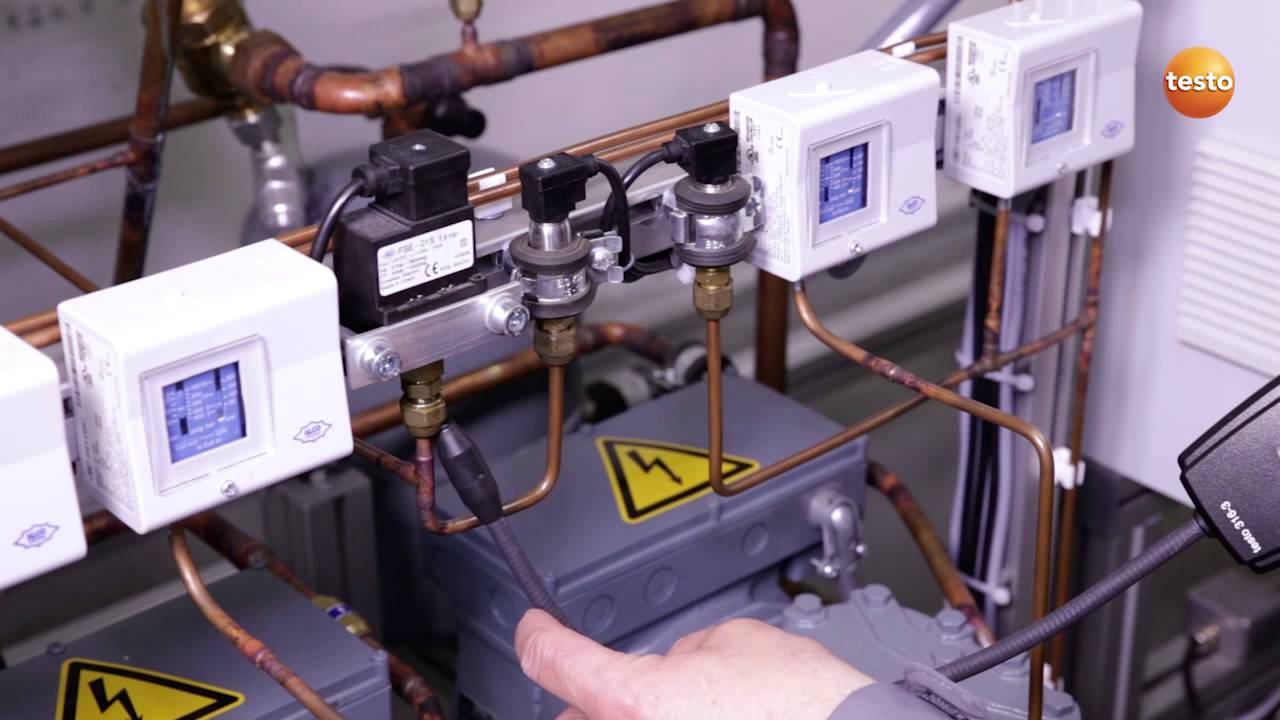

Refrigeration leak detection system. Applications include data centres machinery rooms hotel rooms apartments and. Sensors can easily be integrated into Danfoss ADAP-KOOL systems giving you 247 remote service access to parameters and alarms. In the so-called sniffer technique another variation of the of the positive pressure technique the test gas issuing from leaks is collected extracted by a special apparatus and fed to the leak detector see Fig.

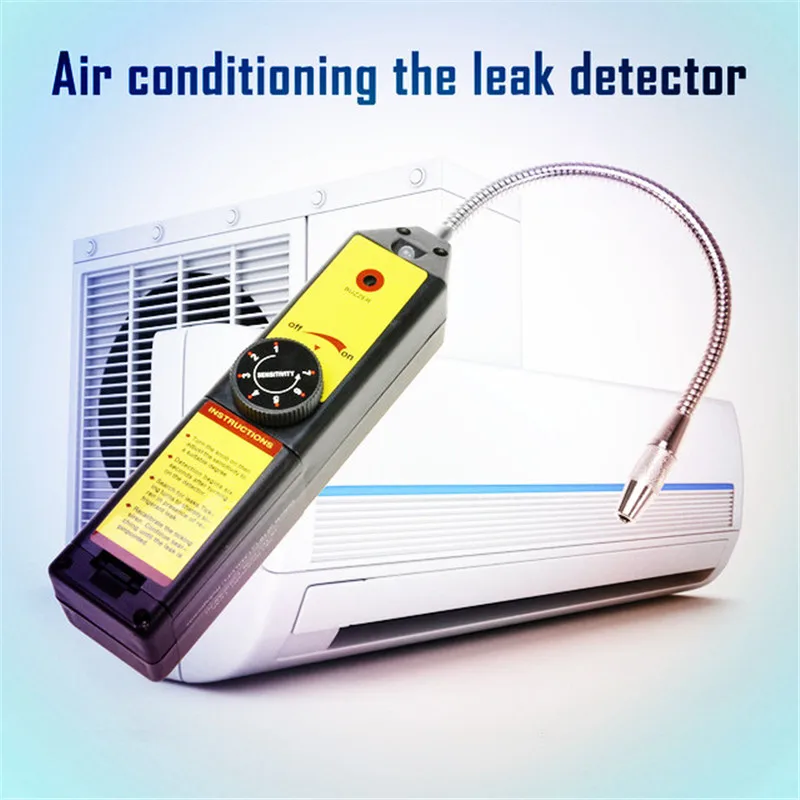

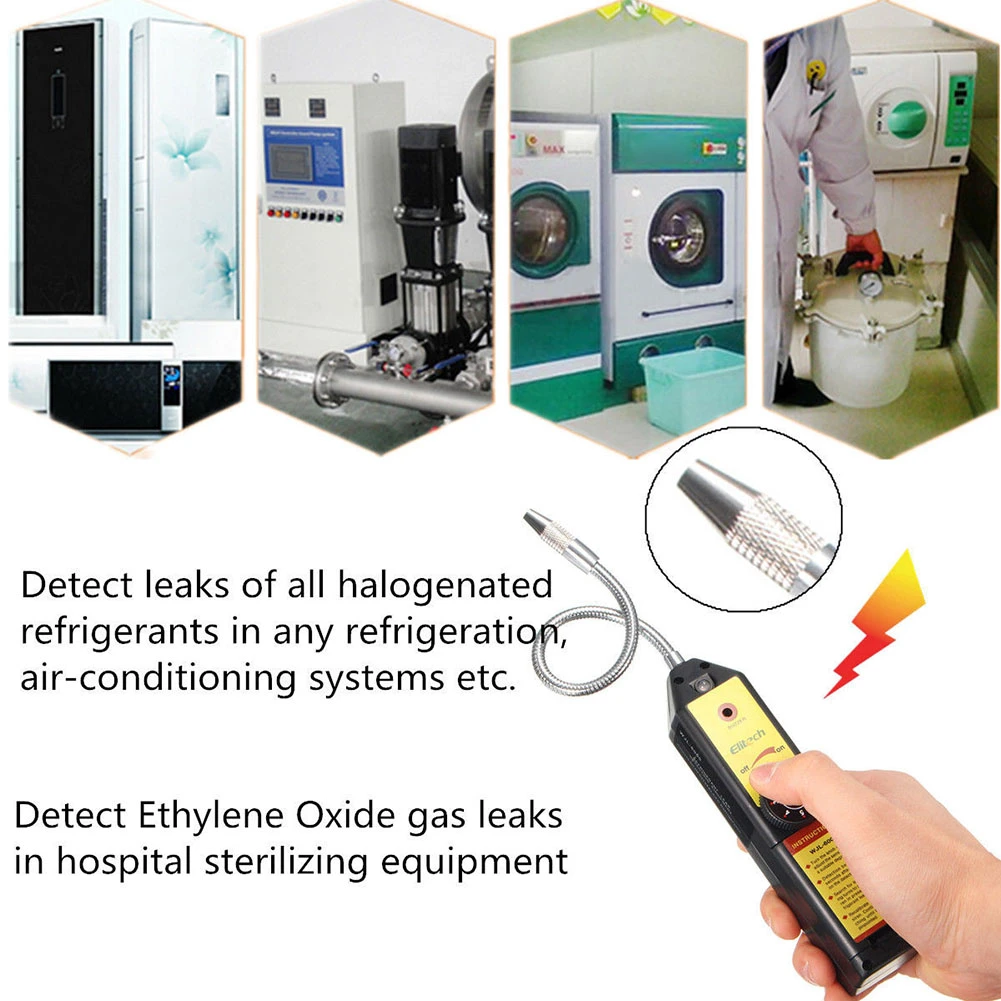

Once the leak is found there are several steps to fixing it. Characteristics of Leak Detection Technologies Active Passive Indirect Sniffer Technology Multiple Zones Tubing to Each Zone Multiple Refrigerants Connection to Monitoring System for Notification Potential to Use for CARB Automatic Leak Detection ALD Passive Infrared Technology Single Zone. Perform a nitrogen purge and pressure test with every new installation to ensure no leaks are present.

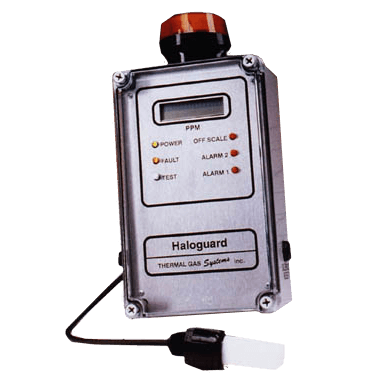

There are several refrigerant leak detection methods that residential technicians can use to find a refrigerant leak and you need to employ the best ones along with the right instrumentation to accurately find and fix refrigerant. All refrigerant leak detection and pump back products are CE certified. In essence Article 4 stipulates that those refrigeration systems with 5 tonnes of CO 2 equivalent tCO 2 e or more must be checked for refrigerant leaks at certain intervals.

It is also illegal to charge a refrigeration system with refrigerant for the purposes of leak detection. Complimented by a full range of flammable and toxic sensors. The bombing testis a special version of the accumulation test see 74.

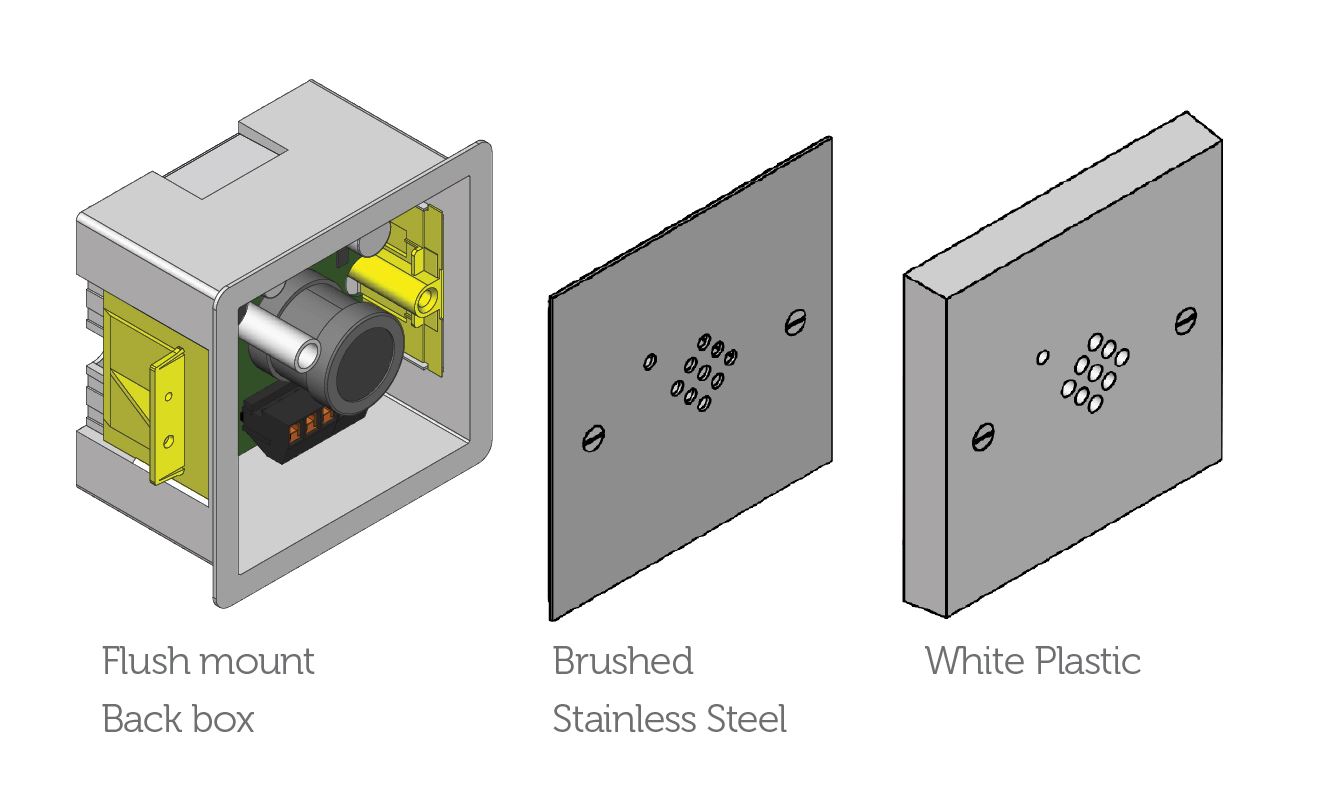

Bacharach MVR-300 refrigerant sensor central monitoring. TCB-LD2UK Refrigerant Leak Detection. An undesired leakage of the refrigerant has to be strictly avoided.

With the new DGS series just 5 models but covers 15. Refrigerant detection system which samples air from potentially contaminated rooms and will alert the necessary individuals. For more information see the REAL Zero guide to the 13 most common leaks.

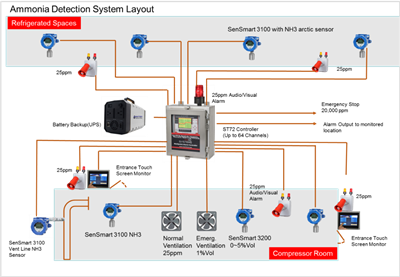

The MRLDS-550 Modular Refrigerant Leak Detection System continuously monitors indoor or outdoor ambient air for refrigerants oxygen and toxic and combustible gases. If you install a system to automatically detect leaks you can double the period of time allowed between leak checks.

Approved by many of the leading classification societies.

Once the leak is found there are several steps to fixing it. If you find somewhere in the system with oil traces probably that is the leakage point. Prohibition or limitation of use with a required implementation of a refrigerant leak monitoring system. The new DGS series gives you long calibration intervals for reduced maintenance costs and sensor heads are easily replaced with a simple plug-and-play process. In some cases the part with the leak needs to be replaced. Once the leak is found there are several steps to fixing it. If you install a system to automatically detect leaks you can double the period of time allowed between leak checks. TCB-LD2UK Refrigerant Leak Detection. During refrigeration system installation use proper securing mechanisms for piping and the correct piping techniques.

Refrigerants are highly toxic and usually very harmful to the environment. Refrigerant Leak Detection 1. In essence Article 4 stipulates that those refrigeration systems with 5 tonnes of CO 2 equivalent tCO 2 e or more must be checked for refrigerant leaks at certain intervals. The MRLDS-550 Modular Refrigerant Leak Detection System continuously monitors indoor or outdoor ambient air for refrigerants oxygen and toxic and combustible gases. Our gas leak detection system utilises plug and play calibrated sensor modules for quick and simple sensor placement. Fill the cooling system with 10-20kg cM2 pressure nitrogen and then smear. Complimented by a full range of flammable and toxic sensors.

Post a Comment for "Refrigeration Leak Detection System"